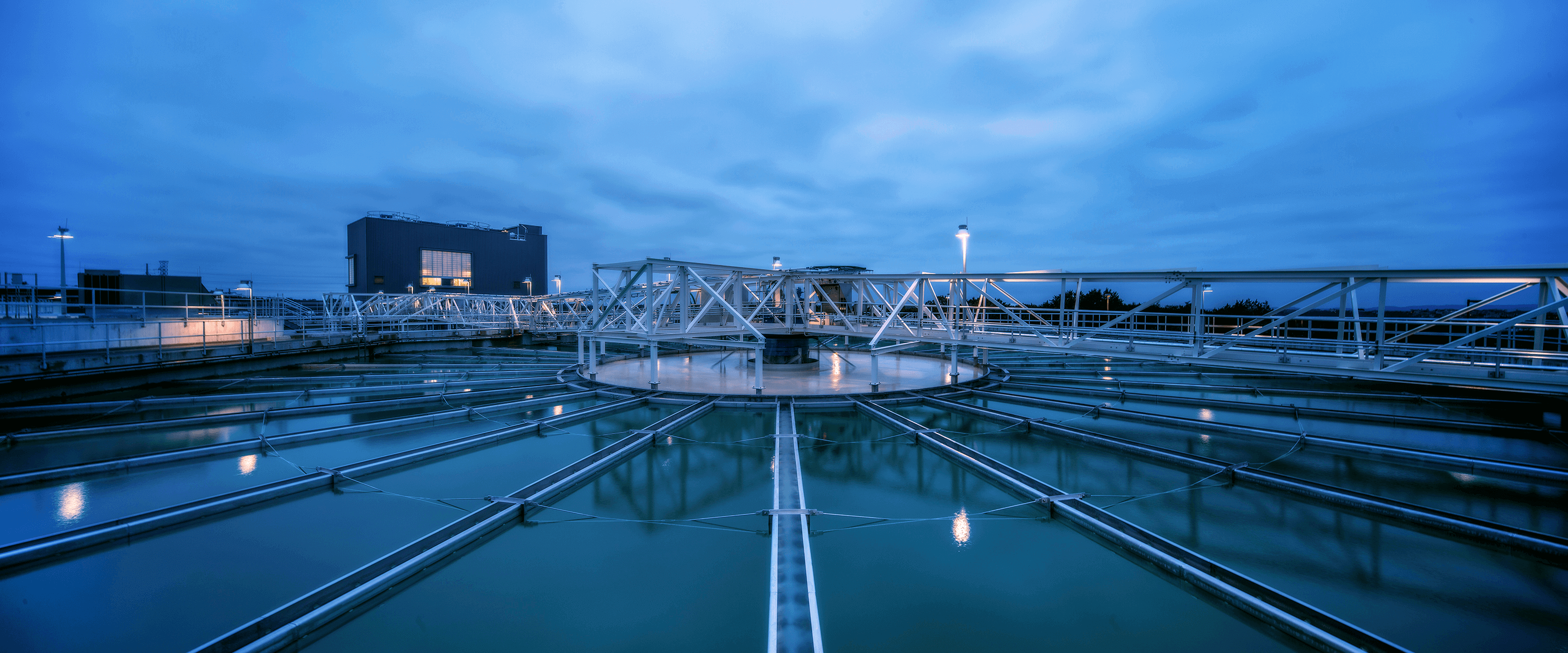

PRETREATMENT SYSTEMS

Need that causes of pretreatment in the design of treatment plants;

- Protection system components

- Protection of sensitive and mechanical units

- Providing physical treatment especially in the early stages to achieve appropriate water advanced treatment

A suitable pretreatment is needed for the high yield purification system

Systems Within The Scope of Pretreatment Plants

- Sedimentation Systems

- Sand Filter

- Multi Media Filter

- Automatic Self-Cleaning Filter

- Activated Carbon Filter

- Disinfection Systems

- Chlorination

- UV

- Ozonation

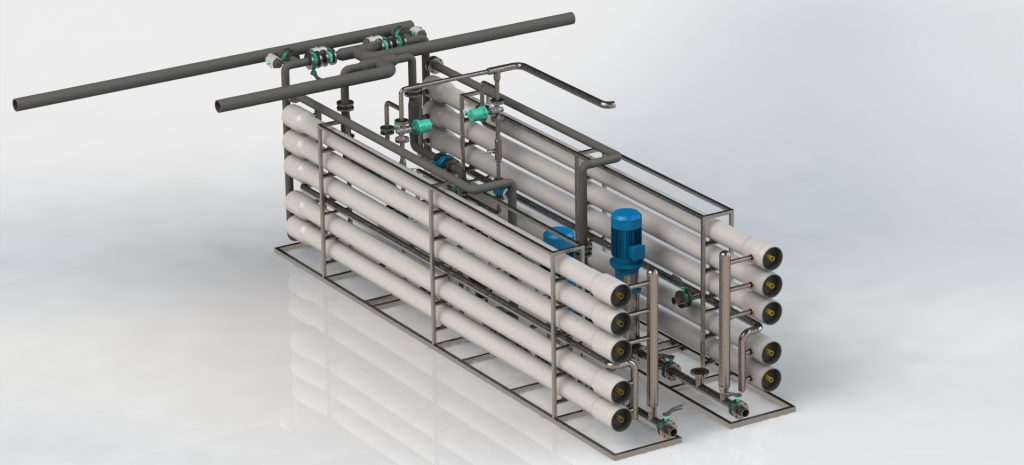

REVERSE OSMOSIS SYSTEMS

These systems are used for lowering the level of the water needs of the ion charge and removal. Reverse Osmosis works by using a high pressure pump to increase the pressure on the salt side of the RO and force the water across the semi-permeable RO membrane, leaving almost all (around 95% to 99%) of dissolved salts behind in the reject stream. The RO water and the solvent passing the membrane, salts and low molecular weight organic material is concentrated. This process requires that a high pressure. RO is especially preferred in well water treatment and desalination processes. RO systems are also widely used in the needs of industrial and other treatment systems.

Systems Within The Scope of Reverse Osmosis Plants

- Coagulation Systems

- Flocculation Systems

- Sand Filter and/or Multi Media Filter

- Automatic Self-Cleaning Filter

- Cartridge Filter

- Activated Carbon Filter

- Membrane Filtration

- Microfiltration (MF)

- Ultrafiltration (UF)

- Nanofiltration (NF)

- Reverse Osmosis (RO)

DEMINERALIZATION SYSTEMS

The removal of the cation and anion ion in water is demineralization process. This process is occurred with using ion exchangers contained in the resin or RO + EDI systems. The demineralization systems are needed in sectors that require advanced treatment such as energy production, pharmaceuticals, paints, petrochemicals and so on. Especially demineralization is used to supply the needs of industrial process water.

Resin Technology

- Coagulation Systems

- Flocculation Systems

- Sand Filter and/or Multi Media Filter

- Automatic Self-Cleaning Filter

- Cartridge Filter

- Activated Carbon Filter

- Cationic Resin

- Anionic Resin

- Mixed Bed

Reverse Osmosis and Electrodeionization

- Coagulation Systems

- Flocculation Systems

- Sand Filter and/or Multi Media Filter

- Automatic Self-Cleaning Filter

- Cartridge Filter

- Activated Carbon Filter

- Reverse Osmosis (RO)

- Membrane Filtration

- Microfiltration (MF)

- Ultrafiltration (UF)

- Nanofiltration (NF)

- Reverse Osmosis (RO)

- Electrodeionization (EDI)

DESALINATION SYSTEMS

Due to limited water resources and challenges of access to natural water sources this system is preferred in recent years. These systems are planned to meet the large amount of industrial water requirement or city water requirement. Reverse Osmosis (RO) systems are usually used for desalinatıon. Desalination systems perform a pre-treatment for treatment plants.

Systems Within The Scope of Desalination Plants

- Coarse and Fine Screen

- Coagulation Systems

- Flocculation Systems

- Sand Filter and/or Multi Media Filter

- Automatic Self-Cleaning Filter

- Cartridge Filter

- Activated Carbon Filter

- Membrane Filtration

- Microfiltration (MF)

- Ultrafiltration (UF)

- Nanofiltration (NF)

- Reverse Osmosis (RO)

- Desal RO

DRINKING WATER TREATMENT SYSTEMS

In our country, drinking and potable water are used for people’s daily activities, drinking, bathing, cleaning. The characteristics that must be present in the water content is determined by the TS 266. Drinking water should not contain any pathogenic microorganisms, chemical substances such as chloride, sulphate, zinc, nitrite and lead should be no more than the amount determined and also color, turbidity, pH should be in the desired properties. Drinking water treatment systems supply not only city and regional drinking water requirements but also industrial drinking water requirements.

Systems Within The Scope of Drinking Water Treatment Plants

- Water Intake Structure

- Raw Water Storage

- Oxidation Systems

- Chlorination

- Ozonation

- Cascade Aeration

- Coagulation Systems

- Flocculation Systems

- Sand Filter or/and Multi Media Filter

- Automatic Self-Cleaning Filter

- Activated Carbon Filter

- Resin Systems

- Membrane Systems

- Process Water Storage

- Disinfection Systems

- Chlorination

- Ozonation

- UV

- Pumping Station

RECOVERY/ ZERO LIQUID DISCHARGE (ZLD)

Zero Liquid Discharge is a process that is beneficial to industrial and municipal organizations as well as the environment because it saves money and no effluent, or discharge, is left over. When the point arrived of water treatment technology and investment costs are considered zero liquid discharge or recycling facilities provide significant advantages for private sector or public companies which have high water demand or using high amounts of water in a particular character in the process.

Advantages of Recovery / Zero Liquid Discharge

- To provide a cost advantage

- Reduction of environmental risks

- Reduction and simplification of environmental management procedures

- Increased efficiency in the whole company

- Ensuring the reduction of environmental risks

- The switch to a more competitive position with environment-quality precision in the national and international market

ZLD systems convert the wastewater source to use raw water source. Thus, it creates a serious economic gain. In the ZLD systems, the most advanced wastewater treatment technologies are used to recycle the almost all of the produced wastewater.

- Discharge water can be recovered in the cooling tower

- Waters recycling of water which is used to treatment of flue gas treatment can be recovered by removing sulfur

- Wastewater which are occurred from process can be recovery and give back to the same system

- Industrial wastewater can be recovered

Systems Within The Scope of Recovery and ZLD Plants

- Balancing and Neutralization Pool

- Coagulation Systems

- Flocculation Systems

- Chemical Precipitation Systems

- Biological Treatment

- Membrane Systems

- Sludge Thickening

- Sludge Dewatering

- ZLD system

DECARBONIZATION SYSTEMS

Decarbonization is a precipitation process with using lime and other chemicals to remove the high alkalinity and also a certain ratio of other ions dissolved in water such as bicarbonates, sulfates, nitrates.

COOLING WATER TREATMENT SYSTEMS

Filtration process occurs especially for cleaning the water contaminated after circulation in terms of SS in cooling towers. Sand filters or mechanical filters are used.

PILOT PLANT

A pilot plant is a small industrial system which is operated to generate information about the behavior of the system for use in design of larger facilities. Pilot Plant is used for a specific area or previously untested process.

MOBILE PACKAGE TREATMENT SYSTEMS

- Industrial Waste Water Treatment Systems

- Domestic Waste Water Treatment Systems

- Industrial Process Water Treatment Systems

- Drinking Water Treatment Systems

DISINFECTION SYSTEMS

There is a need disinfection process drinking water treatment plant output or on the mains. The purpose of disinfection of drinking and process water is to be ineffective form of the pathogenic microorganisms which may be harmful to health. In general, water is disinfected with applying mechanical, physical, chemical, biological and radioactive methods.

Systems Within The Scope of Disinfection Systems

- UV

- Chlorination

- Ozonation

DEGASIFICATION (MEMBRANE CONTACTOR)

Degasification is a method of dissolved gases removal from water. This system is used to keep constant the product water quality values during the process water production or result of treatment process. Conventional and closed system designs are available. Conventional and closed system designs are available. These systems are needed in refinery, pharmaceutical, power generation, food and paper industries.

Systems Within The Scope of Degasification

- O2 Removal

- CO2 Removal

- Ammonia Removal

HEAVY METAL REMOVAL SYSTEMS

Especially in industrial process water supply, heavy metal removal is required according to the process needs. In addition, heavy metals slow metabolic reactions and makes extremely toxic effects to living organisms. In the world, depending on the industrial development, environmental pollution is increasing with toxic heavy metals and dyes. Heavy metals such as Cd, Zn, Cr, Cu, Ni, As and Pb having high solubility in the aqueous medium is absorbed by living organisms. Therefore, the metal containing wastewater should be treated before discharge to the environment.

Systems Within The Scope of Heavy Metals Removal Systems

- Iron Removal

- Manganese Removal

- Copper Removal

- Zinc Removal

- Lead Removal

- Nickel Removal

OIL SERERATION SYSTEMS

Oil separation in contaminated water with oil which is occurred produced from production stage or contamination results is required to reach the discharge criteria and protect the equipment in the system

- Oil – Water Separators (OWS)

- Chemical Sedimentation

- Dissolved Air Flotation (DAF)

Dissolved Air Flotation (DAF) is a method of emülsiye oils and suspended material in wastewater removing from the water by floating. Air bubbles are created in the water with the compressed air to the system. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device.

INDUSTRIAL WASTEWATER TREATMENT SYSTEMS

Industrial treatment systems are used for sending the wastewater which is occurred from the industrial process and production to the receiving environment, network or beginning the process to be used again. Each industrial establishments have different characteristic wastewater generation which its own specific process. In the designs of treatment system, considering these differences special solutions are produced to the customer.

Systems Within The Scope of Industrial Wastewater Treatment Plants

- Oil – Water Treatment (OWS)

- Neutralization

- Coagulation Systems

- Flocculation Systems

- Activated Sludge System

- Sludge Thickening

- Sludge Dewatering

DOMESTİC WASTEWATER TREATMENT SYSTEMS

Domestic wastewater treatment is process creating the appropriate effluent discharge criteria by removing the contamination from the wastewater.

Systems Within The Scope of Domestic Wastewater Treatment Plants

- Grid systems

- Grit and Grease Removal Systems

- Sedimentation Systems

- Nitrification / denitrification systems

- Biological Treatment Systems

- Advanced Biological Systems

- Disinfection Systems

- Grey Water Production Systems

- Sludge Thickening

- Sludge Dewatering

SLUDGE DEWATERING SYSTEMS

Sludge is a product resulting from wastewater treatment. It includes heavy metals and products cannot be treated as biological and also pathogenic organisms come from wastewater (virus, bacteria etc.).

- Sludge Dewatering

- Sludge Thickening

As a result of this process sludge is made contains %20 – 45 solids. Thus, reduction in the amount of sludge is provided as well as an increase in calorific value of the sludge.